1. How to choose plastic gear reducer

The selection of gear reducer should be based on actual needs to select the gear reducer model, technical parameters and subsequent maintenance and other requirements, so as to choose the appropriate specification model, because each mechanical equipment for gear reducer model requirements are not In the same way, when the motor is working, the conditions of the gear reducer movement are also different, so in order to achieve a better use effect and a safer use function, it is recommended that you choose from the perspective of personal needs when choosing In order to avoid unnecessary impacts and losses, it can naturally meet the requirements of using effects in different environments.

Select gear reducer from technical angle:

If the gear reducer keeps the center distance a of the gear transmission unchanged and increases the number of teeth, in addition to increasing the degree of coincidence and improving the stability of the transmission, it can also reduce the modulus and the height of the teeth, thus reducing the amount of metal cutting and saving on manufacturing cost. In addition, reducing the tooth height can also reduce the sliding speed, reduce wear and reduce the possibility of gluing. However, if the modulus is small, the tooth thickness will be reduced accordingly, and the bending strength of the gear teeth must be reduced. However, in a certain range of teeth, especially when the load-carrying capacity mainly depends on the contact strength of the tooth surface, it is better to have more teeth. The closed gear transmission generally has a higher speed. In order to improve the stability of the transmission and reduce the impact vibration, it is better to have more teeth.

Points to note when choosing a gear reducer:

1. Speed: Is there a set speed or speed range, you need the motor to run? If precise or adjustable speed is important, you may need to add a controller to the motor.

2. Torque: How much starting torque does your application equipment require? Will gravity be an obstacle to consider? Does the torque requirement of the motor change during the entire motor operation?

3. Efficacy: Do you think the amount of power required by the application equipment is equal to the actual power used? When providing specifications, determine whether you are using operating power or maximum power.

4. Duty cycle: Will your application equipment run continuously (enough time enough for the motor to reach its full operating temperature) or explode in a short time so that the gear reducer motor cools completely between cycles?

5. Ambient temperature: Will your application equipment operate at extremely hot or cold temperatures?

6. Noise: All gear reducer motors will generate noise due to moving parts, but for some applications in public places or hospital environments, it is important to make the motor run as quietly as possible. Additional noise reduction can be achieved by reconfiguring gears or adjusting materials.

7. Control: Does your application handle fragile items and requires soft start or stop, or do you want to be able to adjust the speed or periodically change the direction of the motor? Can your application run multiple voltages?

2. How to calculate the torque of the gear reducer

Gear reducer torque calculation formula: reducer torque = 9550 × motor power ÷ motor power input revolutions × speed ratio × use efficiency coefficient (with the same motor power and reducer bearing range, the greater the reduction ratio, the greater the output torque of the reducer. The slower the number, the smaller the same reduction ratio, the smaller the output torque of the reducer, the faster the rotation speed)

Motor power calculation formula of gear reducer: motor power = torque ÷ 9550 × motor power input revolutions ÷ speed ratio ÷ use efficiency coefficient

Calculation formula of reduction ratio of gear reducer: speed ratio = motor output revolution ÷ reducer output revolution ("speed ratio" is also called "transmission ratio")

The principle of gear reducer: It uses all levels of gear transmission to achieve the purpose of speed reduction. The reducer is composed of gear pairs at all levels. For example, using a small gear to drive a large gear can achieve a certain speed reduction, and then use multi-stage like this The structure can greatly reduce the speed and increase the role of torque. When the output speed of the motor is input from the driving shaft, the pinion gear is driven to rotate, and the pinion gear drives the large gear movement, and the number of teeth of the large gear is more than that of the small gear. The speed of the large gear is slower than that of the small gear. The output shaft) output, thereby playing the role of output deceleration.

3. How to maintain the planetary gear reducer?

Planetary gear reducer is a very widely used deceleration equipment, widely used in mechanical equipment, engineering construction, industrial manufacturing, consumer electronics, smart home, smart transmission and other fields, in daily operation and maintenance, mainly from two maintenance directions, One planetary gear reducer maintenance, two planetary gear reducer lubrication maintenance.

Planetary gear reducer maintenance:

* Keep the planetary gear reducer clean, adjust and fasten loose parts in time to prevent increased wear and tear of parts or loss of parts due to looseness.

* The end of the run-in period of the planetary gear reducer, the machine should be subjected to mandatory maintenance, check and adjustment work should be done, and pay attention to the replacement of oil.

* For non-standard reducers, operators should receive training and guidance from the manufacturer, fully understand its structure and performance, and obtain certain operation and maintenance experience before operating non-standard reducers.

* Pay attention to the working load during the running-in period. The working load during the running-in period should generally not exceed 85% of the rated working load, and a suitable workload should be arranged to prevent the overheating caused by the continuous operation of the reducer for a long time.

* Pay frequent observations, abnormalities should be stopped in a timely manner to eliminate, and the operation should be stopped before the cause is found and the fault is not eliminated.

After understanding how to maintain the run-in period of the planetary gear reducer, I believe that it will provide us with greater help in future use, which will be more conducive to our use and extend its service life.

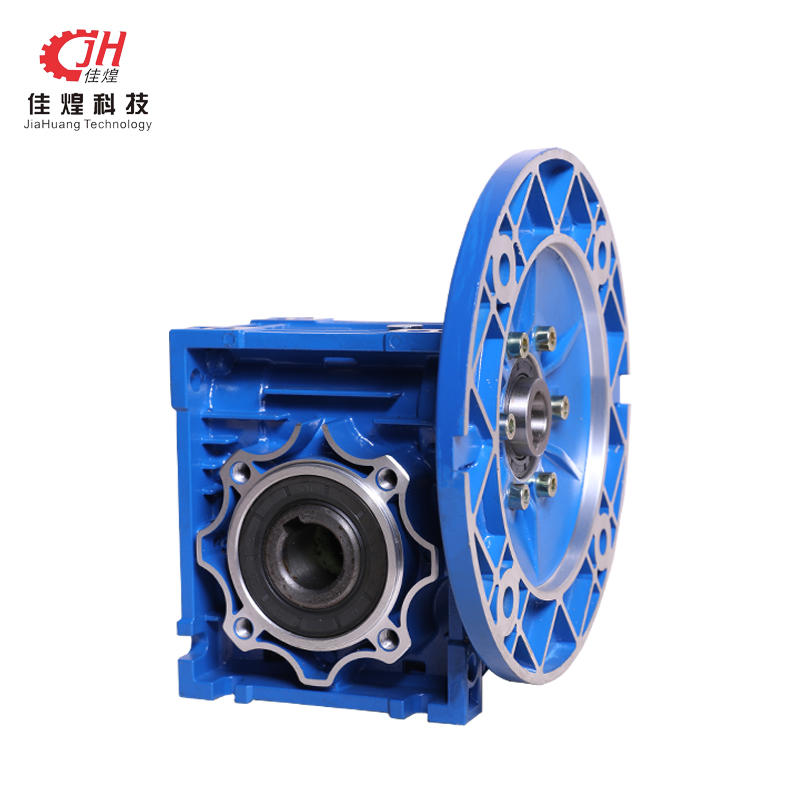

Product name:NMRV Method Worm Gear Blue Reducer Co...

NMRV round flange machine-installation precautions...

Advantage performance: 1.Compact structure, light ...

Product Name:Speed Reducer Die Cast Housing Type:S...

Product Name: Name:Adaptor Flange Colour:Many colo...