1. Inspection hole

In order to check the meshing of the transmission parts and pour lubricating oil into the box, an inspection hole should be set in the appropriate position of the box. The inspection hole is set at the top of the upper case cover to directly observe the gear meshing part. Usually, the cover plate of the inspection hole is fixed on the box cover with screws.

2. Oil level indicator

Check the height of the oil level of the oil sump in the gear reducer, and always keep a proper amount of oil in the oil sump. Generally, install an oil level indicator at the position of the box body that is convenient for observation and the oil level is relatively stable.

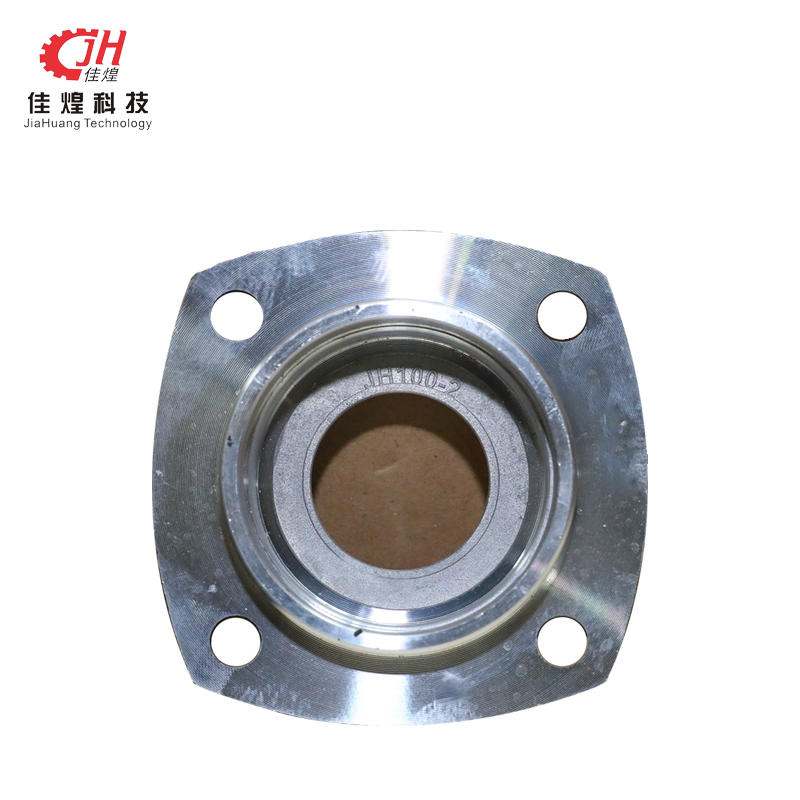

3. Bearing cap

In order to fix the axial position of the shafting components and bear the axial load, both ends of the bearing seat hole are closed with bearing caps. There are two types of bearing caps: flange type and embedded type. It is fixed on the box with hexagonal bolts, and the bearing cover at the extension shaft is a through hole, which is equipped with a sealing device. The advantage of the flanged bearing cap is that it is convenient to disassemble and adjust the bearing, but compared with the embedded bearing cap, it has more parts, larger size and uneven appearance.

4. Ventilator (also called "vent cap")

When the gear reducer is working, the temperature in the box rises, the gas expands, and the pressure increases. In order to allow the hot air in the box to be discharged freely, so as to maintain the pressure balance inside and outside the box, so as not to cause the lubricating oil along the sub-box surface or shaft extension seals, etc. For leakage in other gaps, a ventilator is usually installed on the top of the box.

5. Oil drain plug

When changing the oil, when draining dirty oil and cleaning agent, an oil drain hole should be opened at the bottom of the tank seat and at the low position of the oil pool. The drain hole should be blocked with a screw plug. The joint surface of the oil drain screw plug and the tank should be blocked. Add gaskets to prevent oil leakage.

6. Locating pin

In order to ensure that each time the box cover is disassembled and assembled, the accuracy of the bearing seat hole manufacturing and processing is still maintained, a positioning pin should be fitted on the connecting flange of the box cover and the box seat before finishing the bearing hole. The symmetrical box should be arranged symmetrically to avoid wrong installation.

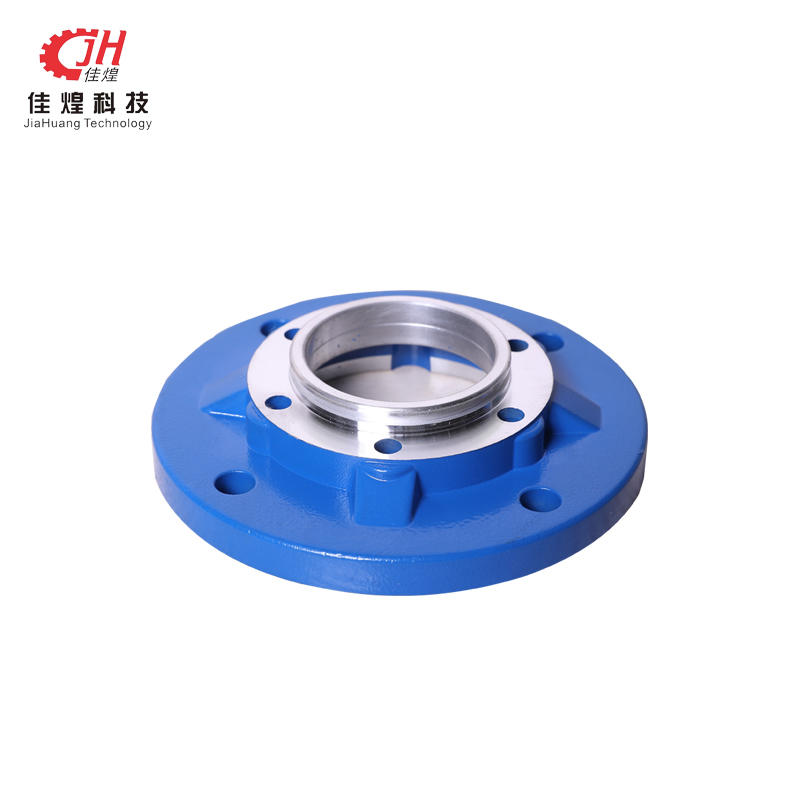

Product name:NMRV Method Worm Gear Blue Reducer Co...

NMRV round flange machine-installation precautions...

Advantage performance: 1.Compact structure, light ...

Product Name:Speed Reducer Die Cast Housing Type:S...

Product Name: Name:Adaptor Flange Colour:Many colo...