The main feature of the worm gear reducer is that it has a reverse self-locking function and can have a larger reduction ratio. The input shaft and the output shaft are not on the same axis or on the same plane. But generally the volume is large, the transmission efficiency is not high, and the accuracy is not high. The harmonic drive of the harmonic reducer uses the controllable elastic deformation of the flexible element to transmit movement and power. The volume is small and the accuracy is high. However, the disadvantage is that the flexible wheel has a limited life and is not resistant to impact. The rigidity is compared with metal parts. difference. The input speed cannot be too high. The advantages of planetary reducer are compact structure, small return clearance, high precision, long service life, and large rated output torque.

Common problems and causes of worm gear reducer

1. The reducer heats up and leaks oil. In order to improve efficiency, worm gear reducers generally use non-ferrous metals as worm wheels, and worms use harder steel. Because it is a sliding friction drive, a lot of heat will be generated during operation, which will cause differences in thermal expansion between the various parts of the reducer and the seal, thereby forming gaps in each mating surface, and the lubricating oil will become thinner due to the increase in temperature, which is easy to cause leakage . There are four main reasons for this situation. One is the unreasonable combination of materials; the other is the poor quality of the meshing friction surface; the third is the incorrect selection of the amount of lubricating oil; the fourth is the poor assembly quality and use environment.

2. Worm gear is worn. The worm wheel is generally made of tin bronze, and the matched worm material is hardened with 45 steel to HRC4555, or 40Cr hardened to HRC5055, and then ground to a roughness of Ra0.8μm by a worm grinder. The reducer wears very slowly during normal operation, and some reducers can be used for more than 10 years. If the wear rate is fast, it is necessary to consider whether the selection is correct, whether it is overloaded, and the material, assembly quality or use environment of the worm gear.

3. The drive pinion helical gear is worn out. It usually occurs on the reducer installed vertically, mainly related to the amount of lubricating oil added and the type of oil. When installed vertically, it is easy to cause insufficient lubricating oil. When the reducer stops running, the transmission gear oil between the motor and the reducer will be lost, and the gears will not get the proper lubrication protection. When the reducer is started, the gears are not effectively lubricated, causing mechanical wear and even damage.

4. Worm bearing is damaged. When a failure occurs, even if the gearbox is well sealed, it is often found that the gear oil in the reducer is emulsified, and the bearings are rusted, corroded, and damaged. This is because the condensate produced by the gear oil temperature rises and cools down after the gearbox has been running for a period of time is mixed with water. Of course, it is also closely related to the quality of the bearing and the assembly process.

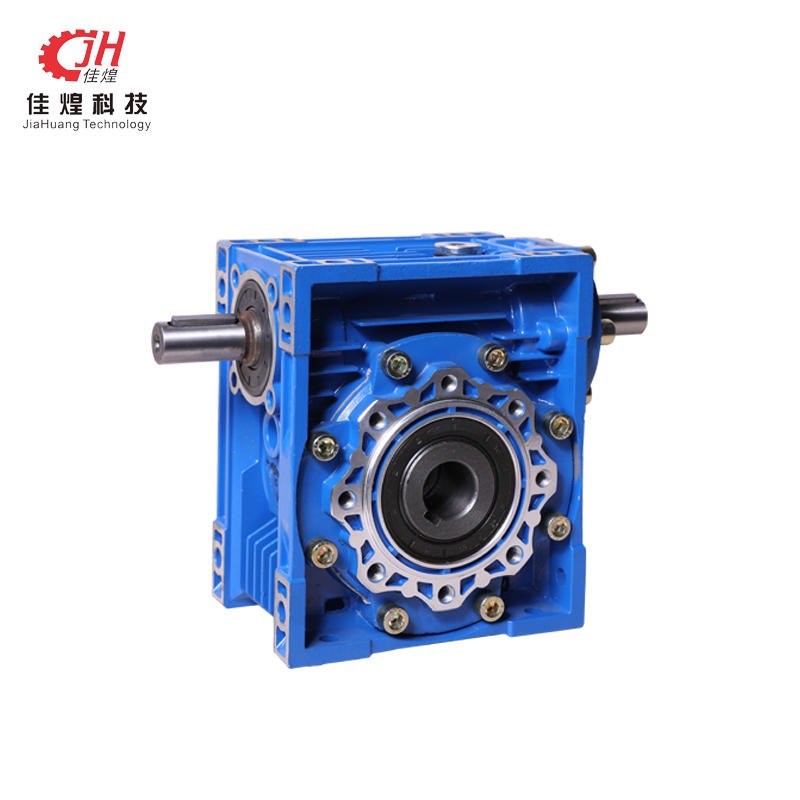

Product name:NMRV Method Worm Gear Blue Reducer Co...

NMRV round flange machine-installation precautions...

Advantage performance: 1.Compact structure, light ...

Product Name:Speed Reducer Die Cast Housing Type:S...

Product Name: Name:Adaptor Flange Colour:Many colo...