Reducer vibration and abnormal sound

Refers to the obvious increase of the vibration and sound of the reducer, which exceeds the normal allowable range, or there is abnormal noise and vibration.

Possible causes: There are many reasons for the abnormal vibration and noise of the reducer, mainly including: gears and bearings damaged, foreign objects stuck in the gear meshing parts, the coaxiality error between the reducer and the motor is large, the gear meshing is not good during assembly, fixed Looseness, loose bolts, dirty lubricant, impurities, etc.

Oil spill

The main reason is the leakage of lubricating oil at the position of the bearing end cover of the reducer, the sealing surface or the joint surface of the housing.

Possible causes: poor sealing, deformation of the case, damage to the case, etc.; or it may be that in the gear transmission, due to the heat generated by the friction, the oil temperature rises and the oil becomes thin and easily leaks. But at the same time, the maintenance of the reducer is difficult, because the cause of the reducer is often inside the reducer box, and it is difficult to check the inside of the reducer box during production operation.

Abnormal heating of the reducer

The abnormal heating of the reducer means that the bearing or housing of the reducer is seriously heated, which exceeds the normal temperature range. It is more common to heat the bearing.

In steel rolling production, overload operation may cause multiple reducers to fail frequently, and bearing wear is common.

Possible causes: Reducer overload operation, bearing wear, improper assembly of bearings, gears, shafts and other parts, voltage is too high or too low, too many start and stop in a short time, poor lubrication, etc.

Daily inspection of gear reducer

1. Check whether there is abnormal vibration and abnormal noise during the operation of the reducer;

2. When the reducer stops running, check the internal parts of gears, shafts and other internal parts through the observation hole.

3. Check whether the oil temperature of the reducer and the temperature of the bearing parts are within the allowable range, and the allowable range should be appropriately adjusted according to the external temperature;

4. Regularly check the cleanliness of the lubricant;

5. Check whether there is oil leakage on the upper and lower joint surfaces of the reducer and the end cover of the bearing.

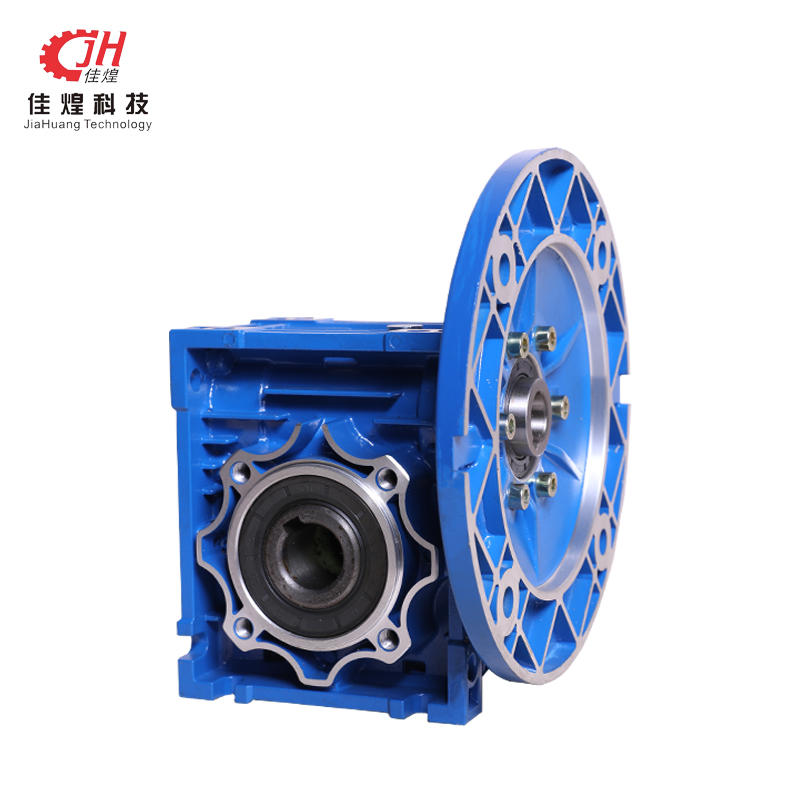

Product name:NMRV Method Worm Gear Blue Reducer Co...

NMRV round flange machine-installation precautions...

Advantage performance: 1.Compact structure, light ...

Product Name:Speed Reducer Die Cast Housing Type:S...

Product Name: Name:Adaptor Flange Colour:Many colo...