For a cylindrical gear reducer with a simple structure, a gear pair constitutes one stage. If multiple gear pairs are switched in sequence, it is called a multi-stage reducer. For each gearbox level, reverse the direction of rotation between the input shaft and the output shaft. The total transmission ratio of the multi-stage reducer is the value obtained by multiplying the transmission ratios of each stage.

Decrease or increase the driving speed according to the transmission ratio factor, which is related to the reduction transmission ratio or the increase transmission ratio. In most applications, a reduction gear ratio is required because the drive torque is opposite to the drive speed and is proportional to the overall gear ratio.

When the transmission ratio is less than about 10:1, the single-stage cylindrical gear reducer has the corresponding technical function. The reason lies in the ratio of the number of teeth. When the transmission ratio is greater than 10:1, the drive gear is very small. This has a negative effect on the gear geometry and the torque that can be transmitted.

For the planetary reducer, the method to realize the multi-stage reducer is extremely simple. Just extend the ring gear and arrange multiple individual planetary levels in series to achieve a two-stage or three-stage reducer. For example, the 20:1 gear ratio of a planetary reducer is a value obtained by multiplying a single gear ratio of 5:1 and 4:1. The planetary carrier uses the sun gear instead of the drive shaft. This type of gear drives the following planetary levels. By further extending the ring gear and continuing to improve the planetary grade, a three-stage reducer can be realized. The transmission ratio of 100:1 is obtained by multiplying the single transmission ratios of 5:1, 5:1 and 4:1. In principle, all single transmission ratios can be combined with each other to realize a multi-stage planetary reducer. The transmittable torque can be increased by additional planetary gears. If the ring gear or the housing is fixed, the rotation direction of the input shaft and output shaft is always the same.

The number of reducer levels increases, and the efficiency of the total reducer decreases. The efficiency at a gear ratio of 100:1 is lower than that at a gear ratio of 20:1. To deal with this situation, when using a multi-stage reducer, the power consumption of the drive stage should be reduced. It can be achieved by reducing the friction loss of the reducer seal or additionally reducing the gear geometry to execute the drive stage. This will also reduce inertia, which is conducive to dynamic applications. The single-stage planetary reducer has the highest efficiency.

In addition, multi-stage reducers can also be realized through various types of gear combinations. Combine a helical gear reducer with a planetary reducer to get a corner type reducer. The total transmission ratio here is also the value obtained by multiplying the single transmission ratio. According to the specifications of the gear type and bevel gear grade, the rotation direction of the input shaft and the output shaft can be reversed.

Advantages of multi-stage reducer:

Wide transmission ratio range

For planetary reducers, always keep coaxial

Compact structure, high transmission ratio

Can be combined with various types of reducers

Wide range of applications

Disadvantages of multi-stage reducer (compared with single-stage reducer):

More complicated structure

Less efficient

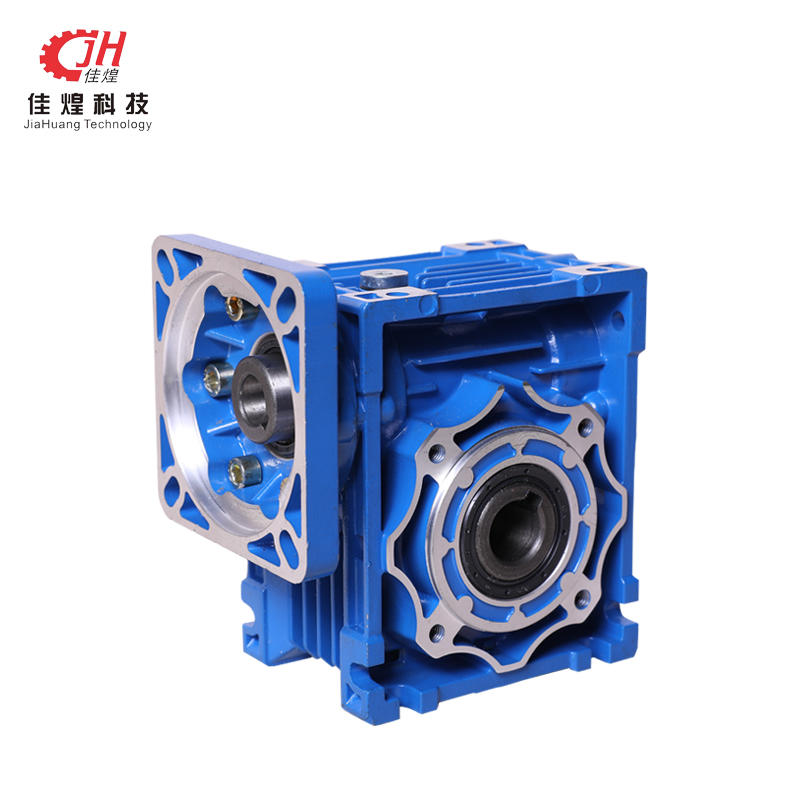

Product name:NMRV Method Worm Gear Blue Reducer Co...

NMRV round flange machine-installation precautions...

Advantage performance: 1.Compact structure, light ...

Product Name:Speed Reducer Die Cast Housing Type:S...

Product Name: Name:Adaptor Flange Colour:Many colo...